About Us

POWERFLEX - NO.1 SUSPENSION BUSHES IN EUROPE!!

EPTG Ltd (European Polyurethane Technologies Group) was formed in the UK in 1996 to take advantage of the significant advances made in the development of polyurethane in recent years.

The company has wide experience in automotive suspension and chassis systems and combining these design skills with advanced polyurethane manufacturing techniques led to the development of a wide range of high performance automotive polyurethane components now known the world over by the product name POWERFLEX.

The company operates in a self-contained state-of-the-art factory, manufacturing everything in-house.

The stainless steel components are machined on the latest computer-controlled equipment to ensure perfect repeatability and quality.

The moulding and tooling, design and manufacturing are carried out within the factory ensuring very rapid response time to special projects and complete communication between development, prototyping, testing and manufacturing departments. Component manufacturing is carried out with the latest automatic processing equipment ensuring 100% right-first-time quality. Testing of new components is carried out both on the vehicle and on test rigs.

POWERFLEX were selected to receive a Queen’s Award for Enterprise International Trade 2013 and in December 2014 certified to ISO 9001 as a manufacturer underlining their quality and stature as a global exporter.

For those unfamiliar with this, it is an international standard to show that the company operates to a system of quality procedures.

For smaller companies, this can be straightforward. Still, for a company of our size with complex manufacturing and over 5000 part numbers, it is a big achievement especially as this was done with no major changes to our rigorous quality procedures.

We were awarded this on our first assessment inspection with no changes or recommendations to the way the business operates. This is a testament to the way we run the business and especially the people within it.

Powerflex is also a proud member of the PAAA - The Performance Automotive Aftermarket Association, a trade-only organisation comprising industry-leading companies that manufacture, distribute, and provide performance parts or services for the European automotive aftermarket sector.

All of these factors combined make POWERFLEX the number one selling performance bush brand in Europe.

OUR RANGES

Road Series – for Road and fast Road use.

POWERFLEX Road Series bushes improve your cars’ road holding and chassis performance by controlling the amount of unwanted flex in the suspension. This means the suspension is doing what it is supposed to. It means your tyres have greater contact with the road at all times, therefore, improving safety and performance. Correctly formulated polyurethane is as good if not better at noise, vibration and harshness suppression when compared to worn rubber. Our Road bushes offer Prolonged tyre life, Improved performance, Increase safety, and Greater cost-effectiveness.

Black Series – for Track and Motorsport use.

POWERFLEX Black Series bushes are manufactured using our Black 95 Shore A compound to provide maximum control of chassis geometry. They are designed for the Track, ready to Race and are engineered to be the best. This compound can be up to 80% more resistant to load than standard rubber and 25% stiffer than our purple performance material. If your requirements are purely for the ultimate in handling and chassis performance then Powerflex Black Series are unique, offering the most precise and accurate alignment for your chassis.

Heritage Collection – for Classic and Restoration use.

POWERFLEX Heritage Collection bushes are manufactured using modern-day materials with properties biased for the road. These dark grey coloured bushes will improve any collector’s car, whilst retaining the same standard appearance of a rubber bush. Our new range speaks to the growing demand for quality replacement parts that have an aesthetic in keeping with’ the look of the original part and restoration project as a whole whilst carrying all of the performance and longevity benefits offered by Powerflex’s unique blend of polyurethane. Going a step further than simply using the same material and durometer of hardness for all of our parts, each part location has its own shore designation to ensure improved suspension performance without discomfort or vibration, all of which ship in our new ‘Classic’ Dark Grey colour suitable for all road-based applications.

OUR MATERIALS

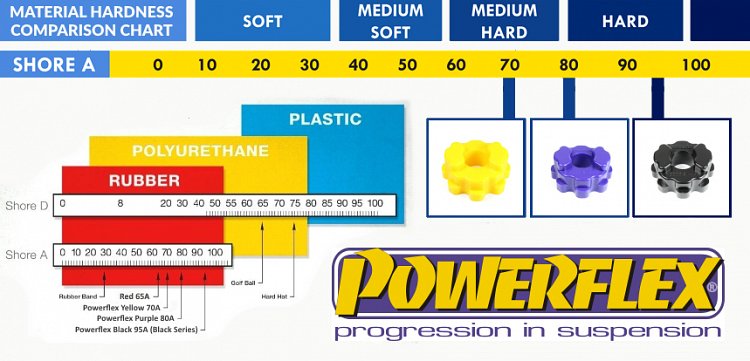

Our materials are colour coded to make them easily identifiable. Below explains the shore rating and their common uses.

Red 65A – Used for our Universal exhaust mounts and diesel engine mounts.

Yellow 70A – Mainly used for engine mounts, diff mounts and subframe mounts or areas where the bush needs a lot of movement and absorption.

Purple 80A – Our most common material. This is used in most areas of the suspension and provides the right mix between performance and compliance.

Black 95A – Our hardest material. This is used mostly for our Black Series range or in our Road Series where the vehicle’s standard suspension demands require us to use this hardness of material i.e. in areas of high load.

Grey* - Used specifically for our Heritage Collection. This can be any of the durometers mentioned but will always be the same as the equivalent part from our Road Series i.e. if it’s Purple 80A in our Road Series, it’d be Grey 80A in our Heritage Collection.

On our Road Series and Heritage Collection kits, we can use a mix of all 4 of our materials. During the development stages, we test the original bush and see what the requirements are for strength and movement. At that point, we then decide which of our materials would be best suited. We don’t believe in a one material suits all rule. Manufacturers will do the same and will use different shore rubbers, however, it’s not as noticeable as all rubber bushes look visually similar.

Can the Road Series be used on ‘Tuned’ cars?

Our Road Series parts would be absolutely fine for ‘Tuned’ cars and Fast Road use. They offer the right compromise between performance and compliance, something that most people require from a daily driven vehicle. Yes, fitting our Black Series parts is possible and has and will be done by many people, but naturally by going even harder with the bushes you are compromising the comfort of the vehicle and therefore you may experience a harsher and noisier ride.

SPECIAL MANUFACTURING

The particular type of polyurethane we use is an advanced material which has unique properties. Our products have the ability to offer high performance without vibration or noise but with an exceptionally long life.

In addition to our “standard” range of bushes, which we publish, we also manufacture many special components for original equipment car companies and also industrial applications.

Because of our manufacturing facility and wide experience with suspension components, we can design and manufacture very quickly bushes and other parts, especially for you.

We manufacture special parts for a number of non-automotive industries. These include marine parts for corrosion protection, shock absorber mounting bushes, sound-absorbing mounting pads, train door mechanisms, rollers, mounting blocks etc.

If you have any special design requirements please contact us.

- Design for track

- Ready to Race

- Engineered to the best

Contact Us for all your bush suspension solutions

We are very proud to be a certified ISO9001 company and receiver of the Queens’s Award for Enterprise and international trade 2013

15th March 2024

NL2024-11 Supra A90 and BMW Z4 G29 Front LCA Bushes with Camber AdjustmentWe are excited to release two new bushes for the Toyota Supra A90 and the BMW Z4 G29.

Read more

8th March 2024

NL2024-10 BMW xDrive Transfer Case Bush InsertWe introduce an easy-to-fit bush insert solution designed to fill the voiding in the OE rubber bush

Read more